-

NEWS

BETOBA ELECTRIC POWER TECHNOLOGY

NEWS INFORMATION

Company News

What is the difference between intensive bus duct and closed bus duct

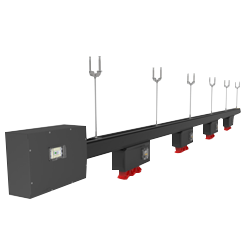

Dense bus duct, a kind of closed bus duct. At present, the bus bar bridge is divided into several generations. The first generation is called bus duct and the second generation is called bus duct. All bus duct are closed, including dense bus duct, air bus duct, fire safety bus duct, fire prevention bus duct, pouring bus duct and so on.

Cooling Method of Intensive Buct

If the temperature of dense busbar is too high, common faults will occur. For the sake of safety, we must pay attention to the way to reduce the temperature of the busbar, in case the temperature is too high to harm the busbar.

Refrigeration Mode of Intensive Bus Duct

If the intensive bus duct temperature is too high, there will be a common fault. For the sake of better safety, it is necessary to master the refrigeration method of intensive busbar to prevent the busbar from being harmed by excessive temperature.

Closed bus duct has the following advantages

Different insulation materials: there is an appropriate gap in the middle of the grounding copper bar of the vapor bus duct, that is, the focus of the insulation layer in the middle of the grounding copper bar is vapor. As everyone knows, the raw material of the insulating layer in the middle of the bus duct (also called closed bus duct in many regions) is the raw material of the analytical chemical insulating layer. Oil-immersed transformer recycling closed bus duct, collectively referred to as the bus duct. Enclosed bus duct and bus duct all refer to the same item.

Characteristics of enclosed busbar

Enclosed busbars are commonly used. Its selection and application have a good safety factor and maintain a good insulation layer of the actual effect. It is a new type of environmental protection material. under the characteristics.

Why is the quality of the whole pouring bus duct of volcanic rock silicon mineral so good?

This product is imported from Europe to China and has been applied for more than 40 years. The product makes full use of the unique physical properties of volcanic silica minerals such as insulation, flame retardant, high temperature resistance, fire prevention, waterproof, air permeability, weather resistance, etc. It not only solves the hidden danger of short circuit of the phase line of the first generation bus. The second generation bus has low insulation level, low protection level and many joint fault leakage points.

10KV volcanic rock silicon mineral full cast bus in power operation

With the construction of power, power facilities and equipment in the harsh environment of the construction of the demand for increased, in order to meet the special environment of the stable operation of power, especially in the salt fog coastal areas or chemical plants containing corrosive, often need to use a higher level of protection of the volcanic silicon mineral full pouring bus.

Materials used for fully insulated busbars

Epoxy resin with particularly good insulation characteristics is selected as the insulator for the fully insulated bus, and its compressive performance can reach above 50000V. Epoxy resin is selected from insulating raw materials, which has the unique advantages of high insulation characteristics, high structural strength and high cost performance of sealing performance. Fully insulated cast busbar with certain spacing in the middle, including resin cast tee joints. Even if the electrical conductor in the fully insulated pouring bus has burrs, it will not destroy the resin insulation layer and cause short circuit fault. Because the fully insulated pouring bus does not have a casing, short circuit fault is unlikely to occur in the middle of the link.

Comparison of Volcanic Inorganic Mineral Full Casting Material and Common Box Bus

The 6.3KV and 3.6KA auxiliary busbars of 330MW units in a coastal power plant originally used common-box busbars. In humid and rainy weather, the insulation resistance of the busbar cut off was greatly reduced, which seriously affected the power transmission operation of the busbar. In large temperature difference or humid weather, dew condensation was easy on the surface of the indoor section busbar and the insulation fixing partition board, causing faults.

SUBSCRIPTION INFORMATION

Product Categories

Contact Us

Address: No. 735, Xinling Road, Shiqi, Panyu District, Guangzhou City, Guangdong Province

WeChat Official Account

Copyright © 2024 Betoba (Guangdong) Electric Power Technology Co., Ltd. All Rights Reserved. Power:www.300.cn SEO license