-

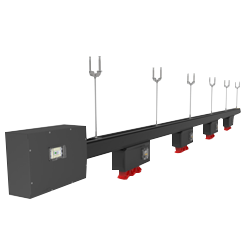

Refrigeration Mode of Intensive Bus Duct

If the intensive bus duct temperature is too high, there will be a common fault. For the sake of better safety, it is necessary to master the refrigeration method of intensive busbar to prevent the busbar from being harmed by excessive temperature.

Low-voltage transmission line wires, electric training, electric system software, branch-intensive network trunking, sapling conductive rods, poor thorn cables, etc. Because different products have different heat removal performance, the current carrying volume of each square wire is also different. The same product, the same specifications and models of wires, according to the same current, when the temperature rises, the heat removal performance will also change; because the total cross-sectional area is different, the temperature rise is not the same. Naturally, when the temperature rises and the resistance increases, the working pressure increases and the kinetic energy damage also increases.

The dense busbar difference is the same. Therefore, it is wrong to calculate the conductivity-intensive bus difference according to the flow per square wire. Product structure design and heat removal, but different characteristic impedance, inductors and other reasons are closely related to the carrying capacity at this stage. Therefore, GB7251.206 national industry standard requirements, the rated voltage limit temperature rise, in order to clarify the bearing capacity at this stage, strengthen the bus duct.

Therefore, the laying of intensive busway must be carried out in the site to carry out accurate measurement, the length of the installation of the wire slot precision provisions higher, intensive busway plug-in distribution box height-width ratio should also be in accordance with the design scheme. When the fire safety distribution line is set, it shall be laid in the structure without incineration body, and the reinforcement protection layer shall not be less than 30mm. When laying, metal pipes or metal material tanks should be used to carry out maintenance with other fireproof materials, because metal pipes and metal material tanks themselves do not have fire safety performance. When the insulation sheath is a cable with non-delayed burning raw materials, the shaft cannot be maintained through metal pipes and metal trunking. However, when the route passes through the wooden floor of the vertical shaft, it must pass through the plate pipe, groove maintenance, left and right pipes, and the gap between the groove holes should also be sealed.

SUBSCRIPTION INFORMATION

Product Categories

Contact Us

Address: No. 735, Xinling Road, Shiqi, Panyu District, Guangzhou City, Guangdong Province

WeChat Official Account

Copyright © 2024 Betoba (Guangdong) Electric Power Technology Co., Ltd. All Rights Reserved. Power:www.300.cn SEO license