-

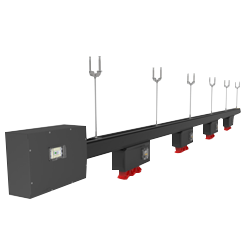

Cooling Method of Intensive Buct

If the temperature of dense busbar is too high, common faults will occur. For the sake of safety, we must pay attention to the way to reduce the temperature of the busbar, in case the temperature is too high to harm the busbar.

1. Low voltage coaxial cable, cable, cable, hair branch dense busbar, bare conductive rod, puncture cable, etc. Since the heat varies with the commodity, the volume of the medium is different per square wire. The same goods, the same specifications and models of wires, if through the same amount of current, temperature rise, heat removal changes. The rise in temperature changes with the cross section. When the temperature rises, the resistance value expands, the working pressure expands, and the kinetic energy loss expands.

2. The compressive strength of the bus duct is the same. Therefore, the electrical conductor of the bus duct with strong conductivity is wrong per square wire according to the steam flowmeter. Although the overall design, heat removal, but not the same characteristic impedance, magnetic induction and other elements of today's carrying capacity is closely related. Therefore, gb7251-2006 to the requirements of the national industry standard, under the setting of the current load working capacity, the temperature rise is limited to the temperature according to the rated voltage, and then the mother pipe is improved.

3. The laying of dense mother pipe must be accurately measured on the spot, and the accuracy of width is very high, and the aspect ratio of the plug box of dense mother pipe must be clear according to the design scheme. When the hidden laying of fire safety wires is selected, it is not suitable for paving in the structure without calcination, and the protective layer of steel bar is less than 30mm. When laying, the metal pipe or metal pipe groove is coated with fireproof material, which is also because the metal pipe and metal pipe groove itself has no fire safety characteristics. When the insulation layer or protective wire sleeve is used as the cable of non-ignition material, the metal pipe can not be applied in the shaft, and the metal pipe can be maintained. However, when the route crosses the shaft layer, the plate pipe and groove maintenance must be applied, and the pipes on the left and right sides must be sealed as well as the gap of the seam.

SUBSCRIPTION INFORMATION

Product Categories

Contact Us

Address: No. 735, Xinling Road, Shiqi, Panyu District, Guangzhou City, Guangdong Province

WeChat Official Account

Copyright © 2024 Betoba (Guangdong) Electric Power Technology Co., Ltd. All Rights Reserved. Power:www.300.cn SEO license