-

Materials used for fully insulated busbars

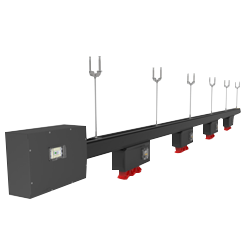

Epoxy resin with particularly good insulation characteristics is selected as the insulator for the fully insulated bus, and its compressive performance can reach above 50000V. Epoxy resin is selected from insulating raw materials, which has the unique advantages of high insulation characteristics, high structural strength and high cost performance of sealing performance. Fully insulated cast busbar with certain spacing in the middle, including resin cast tee joints. Even if the electrical conductor in the fully insulated pouring bus has burrs, it will not destroy the resin insulation layer and cause short circuit fault. Because the fully insulated pouring bus does not have a casing, short circuit fault is unlikely to occur in the middle of the link.

As an anti-corrosion coating, epoxy resin not only has the characteristics of high density, moisture resistance, water leakage resistance and high strength, but also has excellent technologies such as strong adhesion, practical operation at indoor temperature, simple engineering construction, etc. It is not suitable for general resin to cast busbars with full insulation. Experiments show that the insulation resistor will drop sharply at 80 ℃, while the working temperature of full insulation busbars can reach 100 ℃. Even if the temperature reaches 100 ℃, it can still maintain the insulation characteristics for a long time. The thermal expansion coefficient of this type of resin is very close to that of copper. In addition, there is no plastic housing in the bus duct, so it is unlikely that a phase-to-phase short circuit or a phase-to-phase short circuit will occur because the linear expansion is different.

After all, it is fully enclosed, in line with the requirements of the enclosure protection grade XIP according to 68, and water is not easy to enter the bus. This kind of bus duct can be soaked in water for a long time, and can even be used for a long time in corrosive nature. The resin used for the fully insulated bus can also not crack below -50 ℃, and can withstand the impact resistance level above 6 joules, so there is no need to add a plastic shell.

According to GB12666 Class A fire prevention regulation 6-1990, the fully insulated cast-in bus will not break even if it is ignited under fire for 90min at 950 ℃ ~ 1000 ℃. Therefore, the fully insulated cast-in bus can be used as fire prevention bus duct.

SUBSCRIPTION INFORMATION

Product Categories

Contact Us

Address: No. 735, Xinling Road, Shiqi, Panyu District, Guangzhou City, Guangdong Province

WeChat Official Account

Copyright © 2024 Betoba (Guangdong) Electric Power Technology Co., Ltd. All Rights Reserved. Power:www.300.cn SEO license