-

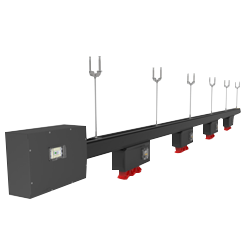

Installation Process and Common Problems of Common Box Enclosed Bus

Installation Process and Common Problems of Common Box Enclosed Bus

Contains isolated phase closed bus, common box (including common interval phase) closed bus and cable bus, commonly used in power stations, substations, industrial production and civil switching power supply wire. Today, we talk about the installation process and common problems of the enclosed bus.

The following special tools shall be prepared in advance before installation of 1. enclosed busbar:

Crane, Hu Lu, soft plastic rope or galvanized steel wire rope with rubber hose, torque wrench, screwdriver, mallet, hammer, impact electric drill, meter ruler, level gauge, wire drop, sand cloth, dust suction machine, cleaning organic solvent, neat white soft cloth, waterproof canvas, screwdriver, safety belt, safety helmet, steel pipe scaffold, elastic wire, switch power supply, etc.

Unpacking and inspection after the 2. enclosed busbar is present:

According to the detailed delivery list of the manufacturer, check whether the total number of enclosed buses and spare parts in the total box is consistent with the delivery list.

Because the enclosed bus belongs to a variety of large and medium-sized products, and the accessories are more expensive, therefore, after the enclosed bus arrives at the construction site, the spare parts must be checked box by box: the delivery list needs to be signed and confirmed by the community owner, project supervisor, manufacturer, installation enterprise and other parties.

Bus inspection can estimate whether the applicable composite insulator is damaged or cracked, whether the bus has shell deformation, scratch, and whether the bus conductor is moving. If the above problems are found, they should be properly handled to facilitate unnecessary rework after bus installation.

Three enclosed busbar installation standards and process flow:

The standard is indoor and outdoor, indoor and outdoor, I .e. installed in place according to the general cad parts drawing of bus, and carry out size adjustment, and finally carry out connection at the fracture surface.

(1) Construction process

Inspection of bus duct → precise measurement and precise positioning → manufacture and installation of seismic support → detection of insulation layer → patchwork of bus duct → phase difference calibration

(2) Construction methods and technical measures for key projects

1) Inspection of bus duct

The quality of the bus duct shall be strictly inspected. The key points are as follows:

A. bus duct casing should be detailed, no damage. Bus duct and distribution cabinet model specifications, specifications and models meet the design requirements. The accessories and supporting facilities are appropriate and the total number is sufficient.

B. The connecting surface of the busbar connector shall be leveled, the connecting hole shall be symmetrical, and the distance from the edge shall be consistent.

c. The anti-static rubber in the middle of the bus bar shall not be damaged or cracked.

D. use 500V megohmmeter to accurately measure the two colors of each bus duct, the neutral row of each phase, the PE row and the insulation layer in the middle of each phase casing, which shall not be less than 20MΩ. The construction site should be cleaned, and try to avoid idle time on the spot. Do a good job in moisture-proof, waterproof work.

(2) Precise measurement and precise positioning of bus duct

A. the installation height and way of bus duct shall be comprehensive and clear according to the construction drawings and the specific conditions of the project. under the condition that there is no conflict with the installation parts of large-diameter pipelines and bridges, the bus duct shall be laid according to the shortest path algorithm of parallel lines as far as possible. the distance from the bottom of bus duct to the road surface is not suitable to be less than 2.5m. The minimum spacing between the surface of the building, other electrical equipment routes and various pipelines shall be in accordance with the national implementation standards.

B. The interval between seismic supports of level installation busway is generally 2~3m, which is decided according to the net weight per meter of busway. Support frame shall be added at the junction of bus duct turn and power distribution cabinet.

SUBSCRIPTION INFORMATION

Product Categories

Contact Us

Address: No. 735, Xinling Road, Shiqi, Panyu District, Guangzhou City, Guangdong Province

WeChat Official Account

Copyright © 2024 Betoba (Guangdong) Electric Power Technology Co., Ltd. All Rights Reserved. Power:www.300.cn SEO license